Strain gauges are components across sectors, as they deliver accurate weight readings by translating physical pressure into an electrical output signal. This process is vital for precise assessments in diverse settings and daily use scenarios. This article explores how load cells work at their most basic level.

The Basics of How Load Cells Work

Load cells work based on principles such as strain gauge technology and hydraulic or pneumatic mechanisms. Among these principles, strain gauge load cells are widely preferred for their accuracy and adaptability. These load cells typically comprise a metal component with strain gauges. When a force is exerted on the element, it alters the resistance of the strain gauges, converting this alteration into a signal that represents the applied force. This is basically how load cells work.

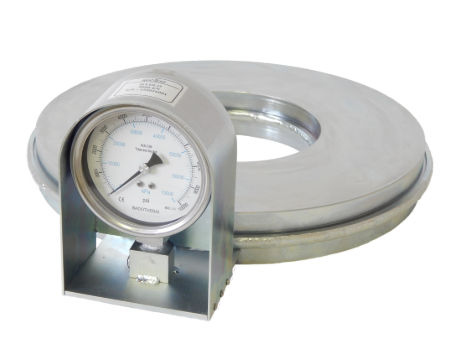

Hydraulic load cells utilize a liquid-filled chamber and a piston to measure force by compressing the liquid when pressure is applied to the piston—a process resulting in a change in pressure. Similarly, pneumatic load cells use air pressure variations for force measurement, making them suitable for environments where electrical parts could be hazardous.

Various Uses in Different Sectors

In the manufacturing industry, load cells play a role in maintaining quality control by weighing materials. Precise weight measurements are essential to avoid production errors minimize waste, and improve efficiency. The transportation sector also relies on load cells within weighing systems to prevent overloading, ensuring safety and compliance with regulations. Load cells play a role in healthcare by being used in monitoring systems to provide precise measurements of body weight and essential vital signs for accurate assessment and care delivery practices.

Varieties of Load Cells

Different kinds of load cells are designed for different purposes. For example, single-point load cells work well for platforms and provide high accuracy in compact spaces, often used in retail scales and smaller packaging systems. S-beam load cells are versatile as they can handle both tension and compression forces, making them a strong choice for testing and material handling tasks.

In truck scales where heavy weights are involved, compression load cells are the choice due to their ability to handle loads and withstand tough conditions. On the other hand, bending beam load cells are ideal for conveyor belt scales as they can handle forces and ensure precise measurements. Both types cater to needs, ensuring stable performance in various situations.

Keeping Things Running

Ensuring that the load cell is properly installed is essential for the accuracy and long-term reliability of the system’s measurement capabilities. Choosing the mounting hardware and securing it onto a surface are key initial tasks in the installation process. Proper alignment of the load cell is vital to avoid any measurement inaccuracies and to optimize its performance. Regular maintenance practices such as calibration and inspection play a role in maintaining accuracy levels over an extended period of time.

Environmental conditions can significantly impact the accuracy of load cells. Ensuring they are shielded from temperatures, moisture, and physical harm can help prolong their durability. Understanding these factors is crucial for upholding the precision of measurement tools in usage scenarios.

Breakthroughs in Load Cell Technology

Advancements in load cell technology persist, with innovations continually being implemented to upgrade the accuracy and data transmission capabilities of load cells. With these enhancements in place, integration with contemporary data systems has become seamless. This has helped to enable real-time monitoring and analysis. Wireless communication technologies also play a key role in improving flexibility by enabling remote monitoring and reducing the necessity for extensive cabling.

With the trend towards miniaturization continuing to grow and evolve in the tech industry, load cells are becoming smaller and more efficient, making them ideal for use in remote devices and systems. As technology advances further, these load cells are adjusting to meet the changing needs of industries, ensuring that they remain valuable and effective tools.

Issues to Address and Factors to Think About

Despite their benefits, load cells encounter difficulties. These are generally changes in the environment, like shifts in temperature, which could impact their functionality. A solution to this issue is opting for load cells that come with temperature compensation capabilities to address these obstacles. It’s crucial to pick the load cell capacity for diverse uses, as a mechanical overload can harm load cells significantly.

Moreover, electromagnetic disturbances may cause disturbances in measurements, requiring protection and grounding considerations to be addressed properly. This ensures top-notch performance and precise measurements in various settings.

In Summary

Load cells play a role in providing measurements in different industries today. Knowing how they work and where they are used showcases their importance in today’s technology. As industries progress and change over time, load cells also evolve to maintain their reliability and accuracy. By integrating these sensors, industries enhance their efficiency, safety measures, and accuracy levels in day-to-day operations.